When integrated supply chain management matters, Axcesor has a ready made solution.

One of the challenges of outsourcing manufacturing of complete products or components is maintaining control of the supply chain. For many subcontract manufacturers, matching master production schedules maintained at client facilities is difficult, especially for small and medium production quantities. Remaining flexible and responsive can turn into a significant coordination task.

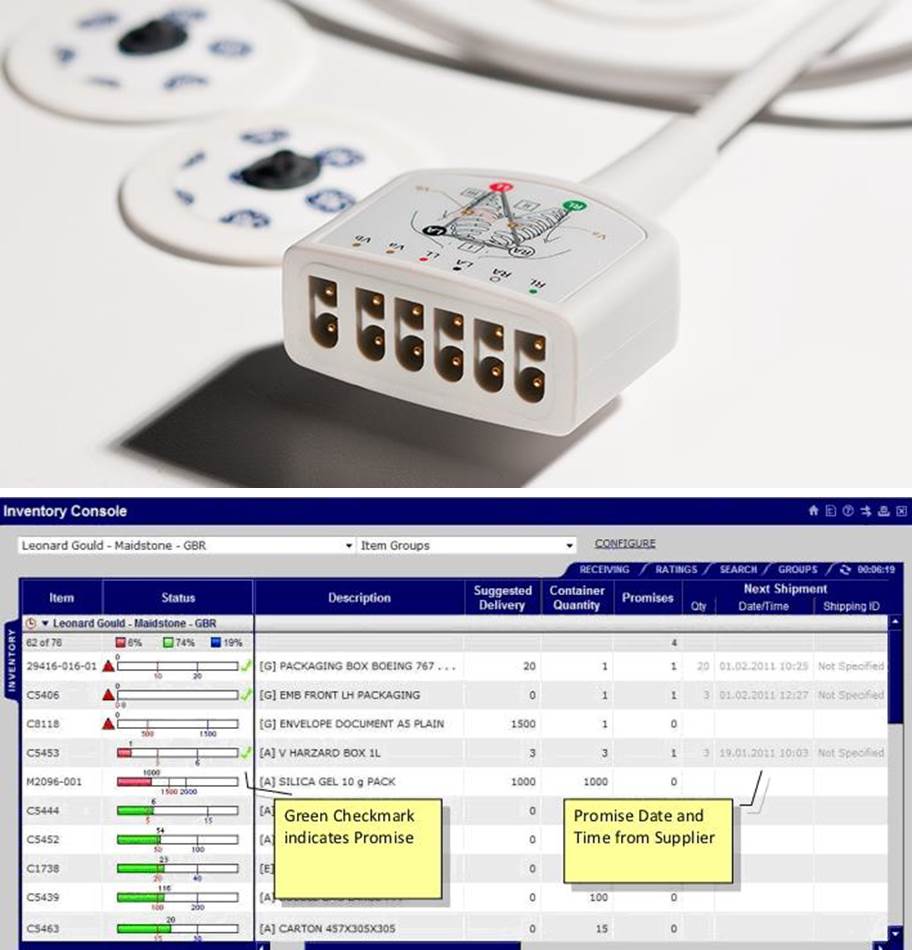

Axcesor has found an excellent solution to this challenge in the form of collaborative supply-chain management software offering called I-Supply. I-Supply collaborative inventory management allows manufacturers to hone in on inventory and shipment issues that make a difference to their business using I-Supply’s state-of-the-art SaaS platform.

This solution proved to be particularly effective in the case of a project Axcesor undertook for a manufacturer of veterinary devices such as catheters and patient monitoring devices.

The work required injection molding, over-molding, ultrasonic welding, electrical testing, bonded light assembly and kitting. Some parts were also purchased from vendors Axcesor depends on for many different projects.

The assembly task was set up within a flex assembly area with assembly procedures and quality checks spelled out step by step. The finished products are packaged and shipped based on the information provided via the I-Supply shared platform.

Order quantities are determined by Axcesor customer service, based on inventory windows set by the customer. Historical order patterns are used to forecast minimum/maximum sub assembly and raw materials quantities to be kept on hand.

Axcesor determines a needed shipment based on where the customer’s inventory is in the window and ships off of a blanket order. Release quantities are determined by the customer: there are no min/max quantities. Axcesor has shipped as little as 50 and as many as 10,000 units. Orders are shipped in boxes via UPS.

Using this SaaS software has made it possible for Axcesor and its client to operate extremely efficiently, maintaining a minimum inventory on had, while at the same time being prepared to deliver product quickly when the need arises.

Contract manufacturing in the US is becoming more and more viable and practical, thanks to increasing labor costs abroad, high quality standards and high level, yet cost effective shared inventory management tool.