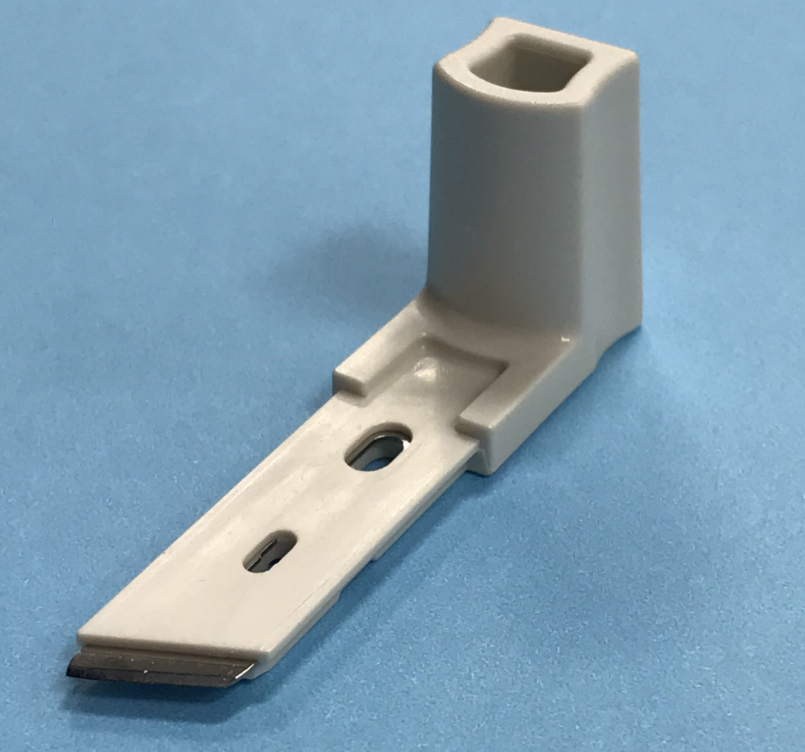

Axcesor has helped a customer launch a new product with an overmolded surgical blade. Often, scalpels with plastic handles are made in a highly automated process by heat staking the blade into the plastic handle, in order to reduce the risk of flash near the blade. For lower or middle volume applications, overmolding is much more economically feasible, but with the challenge of preventing flash at the blade.

Axcesor has achieved zero flash at the blade by using a special plastic insert in the cavity/core of the blade, which provides an interference fit at the blade shutoff. Compressing the blade like this eliminates all gaps at the blade shutoff, thus eliminating flash completely.

After overmolding, the blades are 100% inspected, moved to a cleanroom for packaging, and sent to be sterilized.